Battery Operated Scissor Lift Trackless Transfer Cart

Battery Operated Scissor Lift Trackless Transfer Cart,

agv cart, Intelligent Transfer Carts, railless transfer cart, Trackless Transfer Trolley,

Advantage

• HIGH FLEXIBILITY

Equipped with innovative navigation technologies and sensors, this heavy duty automatic AGV is capable of operating autonomously and seamlessly maneuvering through dynamic work environments with ease. Its advanced features allow it to navigate through complex terrains, avoiding obstacles in real-time, and adapt to changes in production schedules.

• AUTOMATIC CHARGING

One major feature of the heavy duty automatic AGV is its automatic charging system. This allows the vehicle to recharge autonomously, minimizing disruptions in the manufacturing process and saving precious time. The system also ensures that the vehicle remains operational throughout the day, without downtime due to battery charges.

• LONG-RANGE CONTROL

The heavy duty automatic AGV is easy to integrate into existing systems, with the ability to connect to warehouse management systems to improve workflow efficiency. Supervisors can monitor the vehicle’s movements, performance, and operational status from remote locations and proactively address any issues that may arise.

Application

Technical Parameter

| Capacity(T) | 2 | 5 | 10 | 20 | 30 | 50 | |

| Table Size | Length(MM) | 2000 | 2500 | 3000 | 3500 | 4000 | 5500 |

| Width(MM) | 1500 | 2000 | 2000 | 2200 | 2200 | 2500 | |

| Height(MM) | 450 | 550 | 600 | 800 | 1000 | 1300 | |

| Navigation Type | Magnetic/Laser/Natural/QR Code | ||||||

| Stop Accuracy | ±10 | ||||||

| Wheel Dia.(MM) | 200 | 280 | 350 | 410 | 500 | 550 | |

| Voltage(V) | 48 | 48 | 48 | 72 | 72 | 72 | |

| Power | Lithium Battey | ||||||

| Charging Type | ManualCharging / Automatic Charging | ||||||

| Charging Time | Fast Charging Support | ||||||

| Climbing | 2° | ||||||

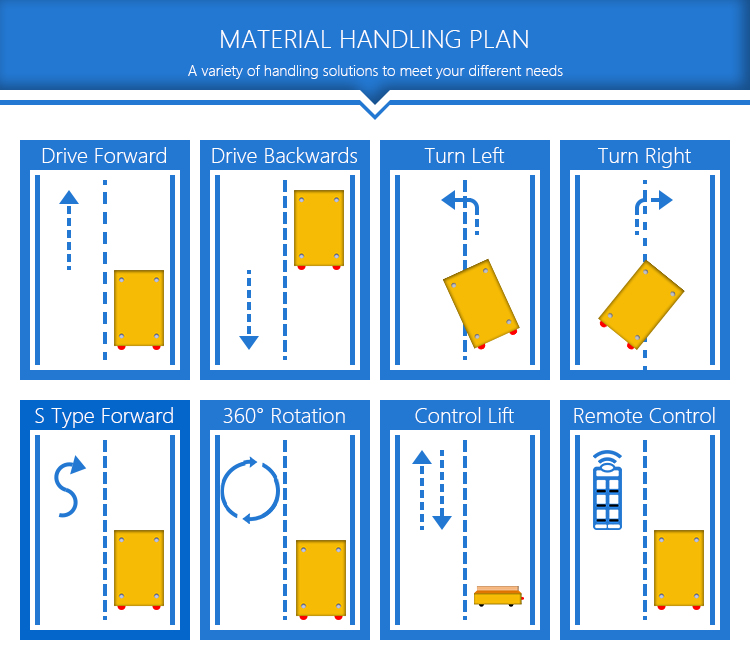

| Running | Forward/Backward/Horizontal Movement/Rotating/Turning | ||||||

| Safer Device | Alarm System/Multiple Snti-Collision Detection/Safety Touch Edge/Emergency Stop/Safety Warning Device/Sensor Stop | ||||||

| Communication Method | WIFI/4G/5G/Bluetooth Support | ||||||

| Electrostatic Discharge | Yes | ||||||

| Remark: All AGVs can be customized, free design drawings. | |||||||

Handling methods

Handling methods

Intelligent AGV material transfer carts can help companies improve production efficiency and reduce work intensity. This vehicle is powered by maintenance-free batteries, which is very convenient to use and is not limited by time. Moreover, this vehicle is also equipped with a scissor lift device, which can freely adjust the lifting height to adapt to different work needs. There is a PLC intelligent control system, which is convenient for staff to remotely control.

Intelligent AGV material transfer carts can help companies improve production efficiency and reduce work intensity. This vehicle is powered by maintenance-free batteries, which is very convenient to use and is not limited by time. Moreover, this vehicle is also equipped with a scissor lift device, which can freely adjust the lifting height to adapt to different work needs. There is a PLC intelligent control system, which is convenient for staff to remotely control.

Material transfer carts are widely used in all walks of life, such as factories, warehouses, logistics centers, etc. They can carry all kinds of goods and easily cope with various working environments. Moreover, the use of this vehicle can greatly reduce the labor intensity of workers and improve work efficiency.

In general, I think the material transfer cart is a very practical tool that will play an important role in various industries. It creates a good working environment, improves production efficiency, and reduces work intensity. The emergence of this handling tool will greatly promote the development of industrial enterprises.